Inject-O-Meter chemical feed systems are simple yet functional in design. These systems are offered in both simplex and duplex styles for maximum versatility. Frame designed for easy portability. Let Inject-O-Meter design and build a chemical feed system for your specific needs.

WEIGHT

85 lbs simplex ,120 lbs duplex (all models except 69-I) Weight for 69-I: 225 lbs simplex, 275 lbs duplex

BENEFITS

- Built rugged for years of trouble free service

- High range of operating pressures (150 psi)

FEATURES

- All wetted parts made of 316 Stainless Steel (other materials available please see the corrosive chemical section in the catalog for details)

- Gear reducer: heavy duty, double shafted (15:1 standard), call for other speeds

- O-rings: Viton®, EPR, Aegis, and Kalrez® for all of your chemical handling needs

- Vee-packing: N-buna, Viton®, Teflon® and special packing with a mixture of 2 styles

- Valves: 316 stainless steel (Kynar®, Polypropylene are available as well)

- Ball Checks: 316 stainless steel (Ceramic and Teflon® are available as well)

- Springs: 316 stainless steel (Hastelloy C available on certain models)

- Tanks sizes: 65 or 110 gallon

- Agitation: air or mechanical

- Plumbing: Polypropylene (comes with everything needed to chemigate)

- MAX-94™ Valve: multi-directional injection check valve needed to meet regulatory laws for chemigation

- Cal-O-Meter™: is the calibration site tube on the system that allows you to monitor the injection rate, made from highly resistant polymers

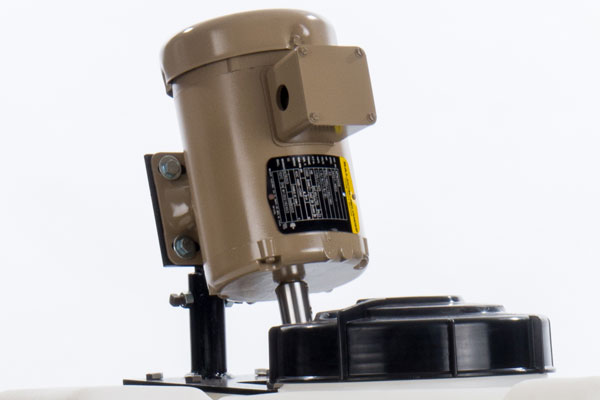

MECHANICAL AGITATION

The agitation is what keeps your product in suspension throughout the injection process. The mechanical agitation can be driven by 3PH, 1PH,or 12 volt motors. The prop and shaft are made of 316 stainless steel for maximum durability. Mechanical agitation is recommended for products that need vigorous mixing to stay in solution. Air agitation (pictured at top) is also available, it is powered by the injection pump. Air agitation is used for products that do not need vigorous mixing to stay in solution.

MAX 94™ INJECTION CHECK VALVE

The Max 94™ injection checkvalve is the distribution point for your chemicals into the irrigation line. This valve is designed to improve the distribution of chemicals in the waterline with a multidirectional atomizing spray. The Max- 94™ is constructed completely of 316 stainless steel with a Viton® seat for strength and chemical resistance. The self-cleaning action alleviates backflow and leakage problems through a positive seating action. The Max-94™ meets or exceeds all state and federal regulations. The Max valve comes standard with all chemigation units sold. Has bleeder valve option as well.

INJECTION PUMP

The driving force behind the Chemigation system is the Inject-O-Meter® injection pump. The pump for your chemigation system can be designed with any combination of the piston sizes we have to offer. Can be made with either simplex or duplex styles. It can be powered by any of the drive options . A variable speed drive can be purchased separately to make the system adjustable while running for added convenience.